How Poor Data Quality is Affecting Your Inventory Management

Keep the good stuff coming

Subscribe to our blog newsletter and get monthly content that helps you manage product data smarter.

No spam. Just real value.

Inventory is a crucial part of any supply chain. Once it’s sold, it becomes revenue.

When inventory doesn’t move, it leads to excess inventory that has the potential to become obsolete or “deadstock.” Both are costly to the company. And this is why inventory management is so important— it helps you keep track of your stock and forecast accordingly.

What does poor inventory data look like?

Oftentimes, businesses use Excel spreadsheets and manual inventory tracking systems. This leaves room for human error, incomplete or outdated information, and siloed data that is spread across departments. It becomes difficult to manage all of that information and ensure it’s updated for all parties in the supply chain, warehouses, manufacturers, and distribution.

A study found that in a sample of 25 spreadsheets, 15 of those spreadsheets contained a total of 117 errors. Out of those errors, seven would be costly to businesses, losing them $4 million to $110 million. This is extremely costly and hinders businesses from making data-driven decisions, improving user experiences, streamlining operations, and enhancing data security.

Smaller businesses often fall victim to this as they use spreadsheets and they struggle to keep up with the inflow and outflow of inventory. This is everything from raw materials to the finished product. Businesses lose an average of 30% of their revenue because of bad data.

This amounts to around $9.7 million and $14.2 million annually.

How poor data quality affects inventory management

1. Accumulating unsellable stock

Ecommerce is a fast-paced industry that’s also ever-changing.

Poor data means your inventory orders and sales projections aren't up-to-date.

For example, let’s look at the annual festive holiday. This becomes a busy time for your staff as they have to get ready to meet customers' demands. You end up looking at outdated historical data and making decisions based on that data. Since it’s inaccurate, you may end up ordering more items than you need and these items can become obsolete and unsellable over time.

Take Nike, for example.

In 2001 they struggled with unsellable stock. They installed demand planning software without adequate testing. This led to overstocking an unpopular item and understocking a best-selling Air Jordans. This mistake cost the sportswear brand $100 million dollars worth of sales.

2. Inadequate forecasting

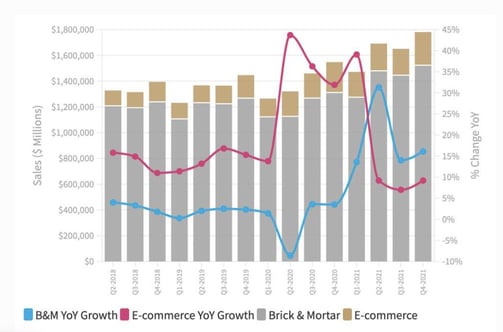

According to Forbes, ecommerce growth has skyrocketed since 2020 as it saw a 50.5% increase over 2019 and a 14.2% increase over 2020. This shows that ecommerce in the United States and all over the world is growing and it isn’t planning to stop anytime soon.

While ecommerce growth is good for business, it also adds pressure to improve forecasting.

According to this study, “65% of companies’ materials management strategies haven’t changed since the beginning of the pandemic.” This means they aren’t nearly close to being ready to manage the spike in product demand and forecasting will fall short. Without accurate forecasting and data, this can affect how brands meet sales predictions and customer demands, lack of stock, delayed times, and more that costs businesses. In 2013, Walmart lost $3 billion because its forecasting did not provide enough clarity on its growth sprout.

3. Running out of key stock

Every business has its best seller/s that customers return for.

However, when you’re not on top of your product data management game, you can easily run out of key stock. This happens when, for example, you aren’t managing your data properly, and your team doesn’t pick up that a product has gained popularity. It also happens when the records of sales weren’t recorded or weren’t updated according to movement. When you make orders, make sure you're basing it on correct information to avoid stock-outs or delays.

4. Decrease in productivity in the organization

Poor data can affect stock management, which impacts the efficiency in warehousing and distribution of your products. Without the right tools, employees will continue to manually manage inventory data, which often leads to poorly labeled inventory and discrepancies that affect the quality of their overall job. According to a survey, over 40% of employees believe they spend a quarter of their workweek doing repetitive tasks. This leads to low productivity.

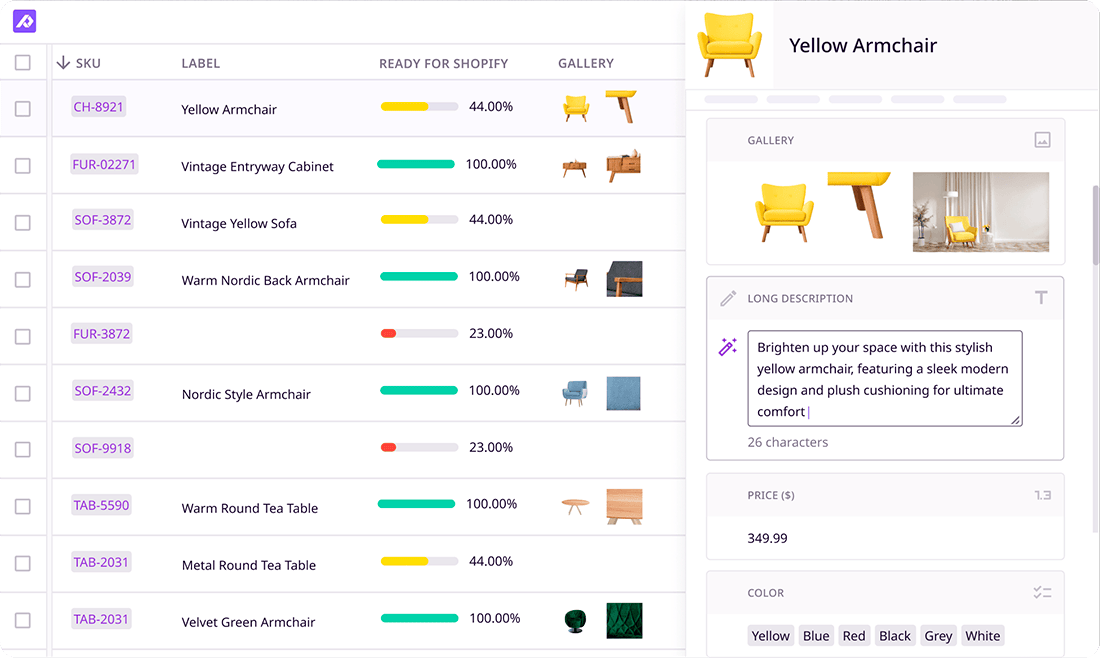

Time to enhance your ecommerce tech stack

You may have an inventory management system or an ERP, but do you have a product information management tool? Now, you may be thinking, “why do I need a PIM tool if I have an inventory management system or even an ERP?” Well, a PIM for inventory management is the final piece to the puzzle to ensure you have strong data management capabilities.

A product database stores and manages product data in a single secure location, whereas your inventory management tool stores inventory-related data. Together, these tools close the gap and reduce redundancies, errors, or lack of information that may affect your inventory.

Are you curious to learn more about our product management tool and how it integrates with software like an ERP to improve inventory management? Download this free white paper!

What if your product data actually worked for you?

We’ll show you how Plytix helps you stop fixing data—and start using it.

Related posts

Keep the good stuff coming

Subscribe to our blog newsletter and get monthly content that helps you manage product data smarter.

No spam. Just real value.

-png.png?width=1280&name=Banner%20The%20Power%20of%20an%20ERP%20and%20PIM%20Connection%20in%20Ecommerce%20(1)-png.png)

Think others should see this?

Go ahead and share it.