Keep the good stuff coming

Subscribe to our blog newsletter and get monthly content that helps you manage product data smarter.

No spam. Just real value.

PDM is a key concept (and software category) for people working with product design and development—so key, in fact, that Kylie Minogue’s even written a song about it (disclaimer: Kylie is yet to publicly admit that Padam Padam is about PDM software, but we’re sure it’s only a matter of time).

If you’re reading this, though, you probably still have a few questions, like:

- What is PDM, or Product Data Management?

- What does PDM software do?

- What are the benefits of PDM?

- How long has Kylie been into ecommerce technology?

Luckily for you, we’ve got the answers (to most of those questions, anyway). Let’s get started.

What is product data management?

Product data management (PDM) refers to the system used to handle files and information related to product design and engineering. Some of the files typically managed by PDM include computer-aided design or CAD files, technical specifications, design drawings, bills of materials (BOM), engineering models, design drawings, and manufacturing requirements.

PDM is all about sharing information in an efficient way, which can make all the difference for a company. After all, anyone working with products in any way knows that there’s a lot of information and data involved and that anything that can make it easier for teams to work on data together is going to come in handy. As a result, PDM can help make product development more efficient, improve collaboration between departments, and make it easier for you to maintain high-quality standards.

Side note: There are people out there who use the term PDM in a more general way, to refer to any sort of process used for managing any sort of data related to products, not just the technical engineering and development side of things. I’m not saying they’re wrong to do this—no judgment here, honest—since that’s literally what the phrase “product data management” means. Still though, in the world of ecommerce it is more typical to hear the term PDM used in the previously mentioned design and engineering context.

Key functions of PDM

So now that we know the general idea of what PDM means, let’s get into some more details. Software and systems used for PDM have a lot of functions and uses—here are four of the top ones to look for.

- Centralizing product-related data: PDM systems store vital technical product data, including safety and sizing information, shipping times, SKUs, and some visual assets. Having all of this in one place means everyone who needs it has access to the latest and most accurate technical information at all times, from engineers and designers to sales, marketing, and distribution teams.

- Improving collaboration and efficiency: As a result of this centralization, PDM makes seamless collaboration possible between different departments. This reduces errors, makes work processes flow more smoothly, and generally boosts productivity. It also allows for better tracking of product changes, which helps avoid errors and again increases efficiency overall.

- Managing files, BOM, and change orders: On that note, PDM systems make it easier to handle large and complex files, control check-ins and check-outs, and oversee engineering change management. This makes sure that all changes are tracked and documented, reducing the risk of data loss or miscommunication.

- Integration with other systems: PDM often acts as the foundation for product lifecycle management (PLM), and the software can integrate with various systems like ERP, product information management or PIM tools, and ecommerce platforms. This integration provides consistent and up-to-date technical data across all stages of the product lifecycle, from design to market.

Advantages of PDM

Those functions are all well and good, but what does all this actually mean in practical terms for you and your business? There are various benefits to having a solid PDM system in place, and these are some of the most relevant ones you need to know.

- Less time and money on product development: PDM lets you centralize your data and automate your workflows, which can majorly reduce the time and costs associated with product development.

- Higher quality standards and less compliance hassle: It’s a lot easier to maintain product quality and meet regulatory standards when you’re consistent with your data management.

- Better teamwork (making the dream work): The collaboration aspect of PDM means even teams scattered across the globe are able to work together efficiently since everyone’s working with the same data and tools, no matter where they are. Fun fact: PIM software can do the same thing for the sales and marketing side of your data—but more on that later.

- Super-secure data and intellectual property protection: PDM systems generally come with robust security features, which let you control access to sensitive data and protect your intellectual property rights.

Your data should be for your 👀 only.

PDM vs other systems

With all the similar-sounding acronyms out there, it’s easy to get confused, especially when half of them seem to follow the pattern P-something-M (looking at you, PXM and the rest). Here’s what you need to know about the key differences between PDM and the two other software types that it gets mixed up with the most, PLM and PIM.

PDM vs PLM

While PDM specifically focuses on managing data during the development phase, product lifecycle management is more general. It looks at the entire lifecycle of a product from start to finish, from initial conception, through design and manufacturing, to the final phases of product use, service, and disposal. PLM integrates and manages data across these various stages, and oversees the product's evolution and modifications over time. This gives you a broader, less narrowly focused, more holistic look at your product's life and a valuable perspective that can help with strategic decision-making and long-term product success.

PDM vs PIM

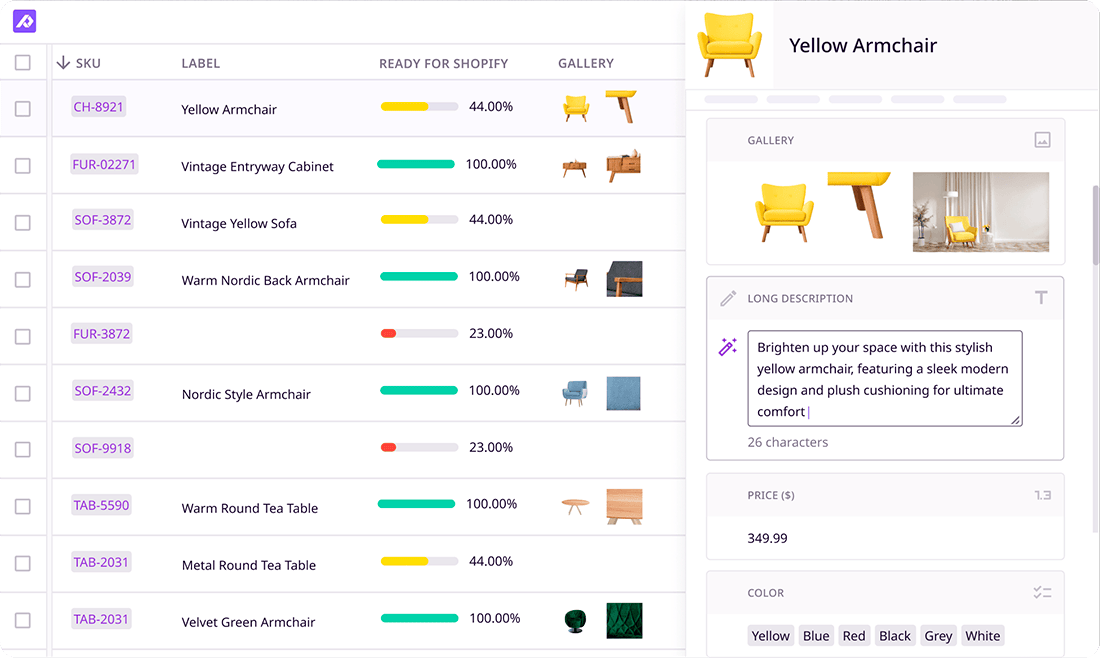

PDM is great for engineering and design data behind the scenes, but while PIM can be used for this too, it’s generally more focused on the customer-facing side of your data. Product information management software helps you manage your product information, distribute it to sales and marketing channels (often automatically), and make sure everything is presented as attractively as possible to potential customers. This often means it comes with digital asset management (DAM) functionality included as well, and it’s a great asset for boosting your sales, reducing time-to-market, and lowering the number of returns caused by data inconsistencies.

Choosing the right PDM system

When selecting a PDM system, it's important to start by thinking about what PDM features you need for your products and your organization, so things like file management capabilities, collaboration tools, and the ability to handle change orders and Bills of Materials (BOM). You want to make sure that it can integrate well with the rest of your tech stack as well—your ERP software, ecommerce platform, product information management tool, and so on.

All in all, product data management is essential for any organization involved in product development and manufacturing. It not only increases the efficiency of the product development process, but also helps with collaboration, reduces costs, and improves the overall quality and compliance of products. As products and markets get more and more complex every day, the role of PDM is getting more and more significant as well as it helps businesses to cope with this complexity and operate more efficiently.

Of course, PDM software isn’t the only tech out there that can take the hassle out of selling online. There’s a whole bunch of other software you can benefit from as well, from DAM to inventory management to ERP systems. Want to learn more about some of these other tools? Well then, as luck would have it, there’s an ebook waiting for you right here.

Frequently Asked Questions

Product Data Management (PDM) refers to the system used to handle files and information related to product design and engineering. It includes managing various types of files like CAD files, technical specifications, design drawings, bills of materials (BOM), and manufacturing requirements. PDM is crucial for efficient information sharing, which can significantly improve product development, improve collaboration between departments, and maintain high-quality standards.

PDM software serves several essential functions, including centralizing product-related data (like technical details, safety information, and visual assets), improving collaboration and efficiency across departments, managing files and change orders effectively, and integrating with other systems like ERP, PIM tools, and ecommerce platforms. These functions ensure seamless access to accurate technical information and enhance productivity and data consistency throughout the product lifecycle.

The benefits of using PDM include reduced time and costs in product development due to centralized data and automated workflows. It also ensures higher quality standards and easier compliance with regulatory standards. Additionally, PDM facilitates better teamwork, even with globally dispersed teams, and provides robust security features for data and intellectual property protection.

PDM focuses on managing data specifically during the product development phase, while Product Lifecycle Management (PLM) encompasses the entire lifecycle of a product, from conception to disposal, integrating data across various stages. On the other hand, Product Information Management (PIM) is geared towards managing customer-facing product information, distributing it across sales and marketing channels, and ensuring attractive presentation to customers. PDM is more technical and engineering-focused, whereas PIM is more about marketing and customer engagement.

No comment, but I did hear that she wrote “Can’t Get You Out Of My Head” after trying Plytix PIM software the first time 🙊

What if your product data actually worked for you?

We’ll show you how Plytix helps you stop fixing data—and start using it.

Related posts

Keep the good stuff coming

Subscribe to our blog newsletter and get monthly content that helps you manage product data smarter.

No spam. Just real value.

Think others should see this?

Go ahead and share it.